In the sophisticated structure of electric equipment, the stator, as a silent yet critical core component, serves as the hub where the stator enables the conversion of electrical energy into mechanical energy. Derived from the combination of Stationary and Rotor, the term "stator" not only defines its physical property but also reveals the stator's irreplaceable functional role in motor systems. From industrial heavy machinery to household intelligent devices, the stator, with its stable static structure, has become the invisible force—powered by the stator's design—that drives the operation of the modern electrified society.

The Essential Definition and Core Functions of the Stator

The stator is a key stationary component in motors, and the stator's core mission is to generate a magnetic field through current excitation, with the stator providing driving force for rotor rotation. When three-phase current flows through the stator windings, the stator forms a rotating magnetic field in space. The interaction between this magnetic field (created by the stator) and the rotor produces torque, achieving the conversion of electrical energy into mechanical energy. Figuratively speaking, the stator is like the creator of the magnetic field, with the stator providing a stable magnetic environment for motor operation by precisely controlling the electromagnetic induction process.

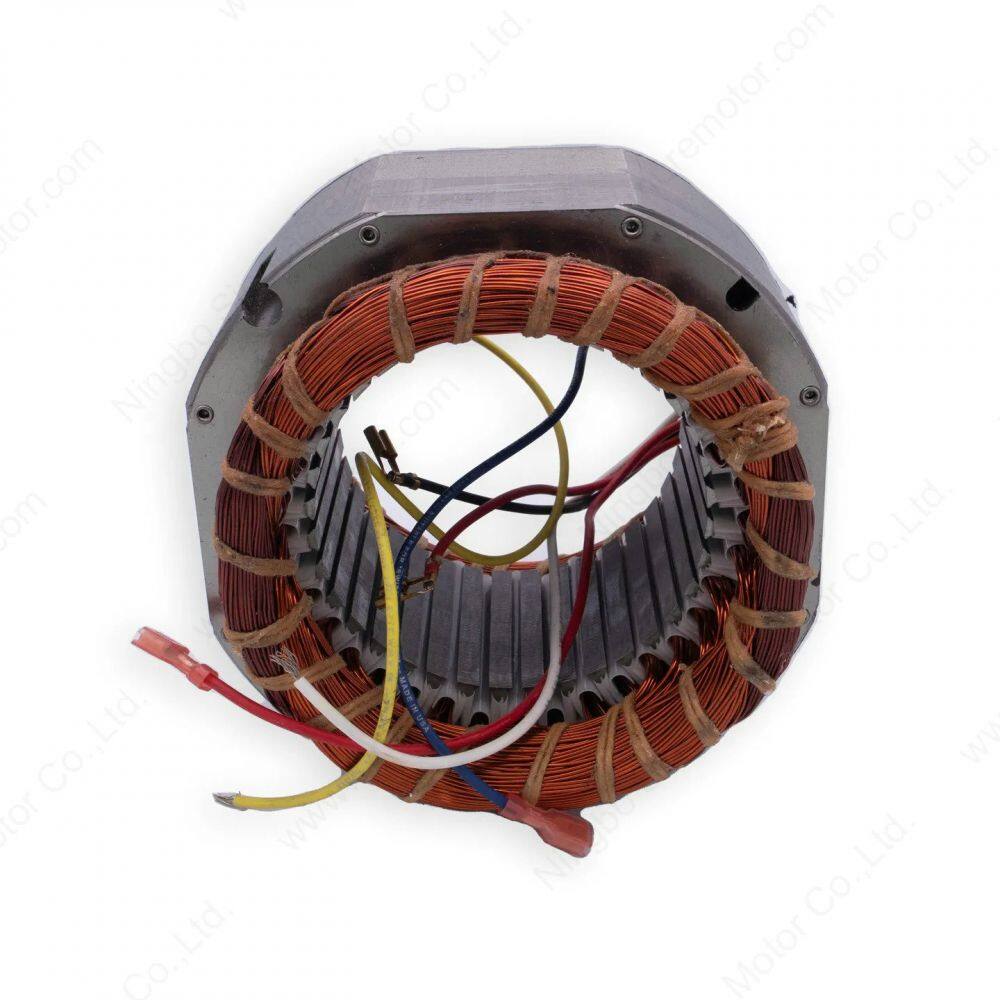

In terms of structural composition, the stator mainly consists of three core parts that make the stator functional:

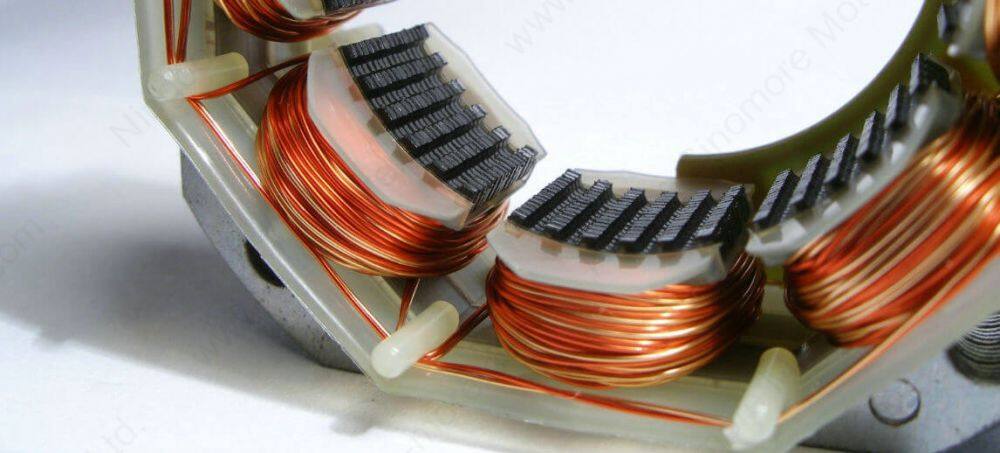

Stator Core: The stator's core is formed by laminating silicon steel sheets with a thickness of 0.1-1.0mm; this design not only enables the stator to conduct magnetism efficiently but also reduces eddy current loss through insulating coatings. The silicon element in the silicon steel sheets further optimizes the stator's magnetic permeability and reduces hysteresis loss, making it an ideal material for the stator's magnetic conduction.

Stator Windings: The stator's windings are wound with insulated copper wires and embedded in the slots of the core. When current passes through the stator windings, the stator generates an alternating magnetic field, serving as the energy source driving the motor.

Housing Structure: The stator's housing not only provides support and protection for the stator but also ensures the stator maintains a reasonable temperature during high-frequency operation through heat dissipation design, guaranteeing the stator's and the system's stability.

Technical Types and Application Scenarios of the Stator

Depending on the type of motor, the stator's structural design—tailored to the stator's specific role—exhibits diverse characteristics to adapt to energy conversion requirements in different scenarios:

Stator for AC Motors: The Precision Carrier of Rotating Magnetic Fields. In AC motors, the stator typically has a cylindrical structure, with the stator's core formed by laminating toothed silicon steel sheets, and the stator's three-phase windings embedded in the slots. When alternating current passes through the stator windings, the stator forms a rotating magnetic field in space, which interacts with the rotor to produce torque. Such stators are widely used in industrial drive systems, household appliances, and other fields, where the stator's design precision directly affects the speed stability and energy efficiency of the motor.

Stator for DC Motors: The Stable Provider of Fixed Magnetic Fields. The stator of a DC motor mostly adopts a cylindrical steel armature, with the stator's internal installation of magnetic poles and coils. Excited by direct current, the stator generates a fixed magnetic field, which—driven by the stator's design—interacts with the armature windings of the rotor to drive rotation. This type of stator is commonly used in scenarios requiring precise speed control, such as drive motors for electric vehicles and precision servo systems, where the stator's magnetic field stability determines the operational accuracy of the equipment.

The Key Role of the Stator: A Decisive Factor in Motor Performance

The design and manufacturing quality of the stator—since the stator is the heart of the motor—directly affect several key performance indicators of the motor:

Energy Efficiency: High-quality stators, through the stator's optimized magnetic field distribution and reduced losses, can increase motor efficiency by 10%-15%, lowering long-term operation costs.

Service Life: Reasonable material selection for the stator (such as high-permeability silicon steel and heat-resistant insulating paint) and the stator's structural design (such as heat dissipation rib layout) can extend the stator's service life by more than 20%.

Operational Stability: The uniformity of the stator's magnetic field determines the smooth operation of the motor, with the stator reducing vibration and noise and enhancing equipment reliability.

Environmental Adaptability: Special coatings and sealing designs for the stator enable the stator to work stably in harsh environments such as humidity and dust, expanding the stator's application scenarios.

Conclusion: Join Hands to Open a New Chapter in Stator Technology

In the surging wave of global electrification, Sinomore, with years of technical accumulation in deepening motor core components—especially the stator—has brought a series of high-reliability and high-performance customized stator and rotor products to the market, with the stator as a core focus. We have established a full-chain service system from material processing for the stator, component manufacturing of the stator to performance testing of the stator. Each set of products undergoes multiple precision inspections, covering stator core permeability testing, stator winding withstand voltage testing, rotor dynamic balance detection, etc., to ensure that the delivered motor core components—with the stator at their center—reach industry-leading levels in energy efficiency, reliability, and environmental adaptability.

Whether it is a green energy project pursuing ultimate energy efficiency or high-end manufacturing equipment with strict precision requirements, we can provide one-stop services for the stator from scheme design to production delivery according to your needs. We look forward to cooperating with you, leveraging excellent technology and services for the stator to jointly explore the infinite possibilities of motor applications—powered by the stator—and inject new vitality into industry development!

Read More

Read More Read More

Read More